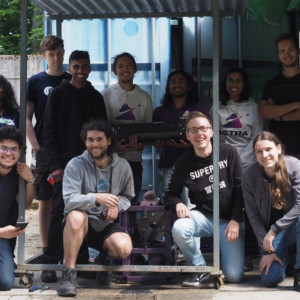

In May, the propulsion team of ASTRA achieved a very important milestone. The team successfully tested the propulsion system and fulfilled the requirements imposed by our system engineers for our future launch.

I am Taro Tokita, currently the team lead of the propulsion team of ASTRA and I would like to tell you about the testing campaign of ASTRA’s new propulsion system. In simple terms, in the campaign we tested whether our engine works. As mentioned, the test was very successful and we were actually very efficient being able to hot fire twice on several days. But let’s start from the beginning!

Before we started with the actual hot fire testing though we had to pressure test our aluminium/CFRP (carbon fiber reinforced polymers) tank that the structures team of ASTRA made. Sadly, we experienced our biggest failure for the campaign here and the tank did not hold the required pressure of 90 bar (1.5 x). However, we were prepared for this situation and switched to the second tank that we brought which was made from steel and CFRP. This tank passed the test and so we could quickly continue our testing without longer hold ups.

Next, we characterized our injector plate with cold flow testing. These tests showed that our injector plate is kind of inefficient as it has a low discharge coefficient (this number describes the pressure drop that occurs when a fluid flows though the injector). As we realized later on this was actually better for us as this limited the oxidizer mass flow into the combustion chamber. Also, with these tests we leak proofed the setup and as there were no other anomalies we continued with the first hot fire test, a 2s burn!

For this first hot fire test everyone was nervous and slightly on edge. With all kinds of thoughts in our minds we assembled the test setup of the engine. After the last steps of sensor preparation were done, the team entered the control room to commence the filling operation of the tank. This was done via the ground systems in house built control unit. To our delight filling worked perfectly without any problems. Then, it was finally time to light the engine.

Countdown: 5, 4, 3, 2, 1, Ignition!

We saw the smoke from the Igniter exiting the nozzle. Then we saw how a lot of nitrous oxide exited the nozzle as well… For some reason, the fuel mixture did not catch on fire. This was confusing at first but after we took apart the motor, we realized that the problem was that one single Igniter did not produce enough heat to get the combustion reaction going. So this was an easy fix and we just used 2 Igniters. We assembled the system again and after the last steps of the setup we entered the control room hoping to see a flame this time.

Again, countdown:

5, 4, 3, 2, 1, Ignition!

Again, we saw the Igniters going off and then the engine fired and this was one of the most glorious moments of the campaign. We had no anomalies and no leaks, although the thrust generated was just slightly short of the target. By all accounts this was a near perfect result!

The burn ended after 4s which is 2s more than what was planned. As we later found out, our main flow valve that controls the oxidizer flow into the chamber, cannot handle the liquid oxidizer flow and will only close as soon as the nitrous oxide changes to the gas phase. But now that we had proven that the engine works, we could continue testing and we directly went for a full duration test of 8s. We were able to replace the broken parts and the solid fuel grain and performed the next test on the same day. This test also showed no anomalies and therefore we could continue the campaign without any changes to the system. During the 3rd burn the nozzle partially eroded/melted so we replaced the nozzle with the second nozzle we brought. With the 3rd burn we also accumulated 2 similar thrust curves that we needed for one of the our launch requirements. Technically, we achieved our main goal.

With all subsequent tests we tried out different things. First, we included a Vortex plate that would mix the propellants in the chamber to increase efficiency. This worked very well for us and we also generated 2 similar thrust curves with this setup. This means that we could also fly with this setup at EUROC. Next, we also used a fuel grain that includes aluminium power. However, the powder was deposited in the outer most 2mm of the grain due to a centrifuge effect during the grain spinning process. Thus, this did not have a significant effect on the burn behaviour.

In the end we were able to perform 7 tests in 4 days, reached a peak thrust of over 7kN and fulfilled the requirements of our system. The next steps now are to evaluate all the data and to prepare for the launch at the end of this year.

I hope you enjoyed reading this blog entry and it gave you some insight about what is happening at ASTRA. Thank you for staying until the end, and don’t forget to expand your horizons!

For more information, pictures and videos: definitely check out our YouTube channel where a video about this testing campaign is published.